T. R. Miller Mill Company

"The Natural Choice Since 1872"

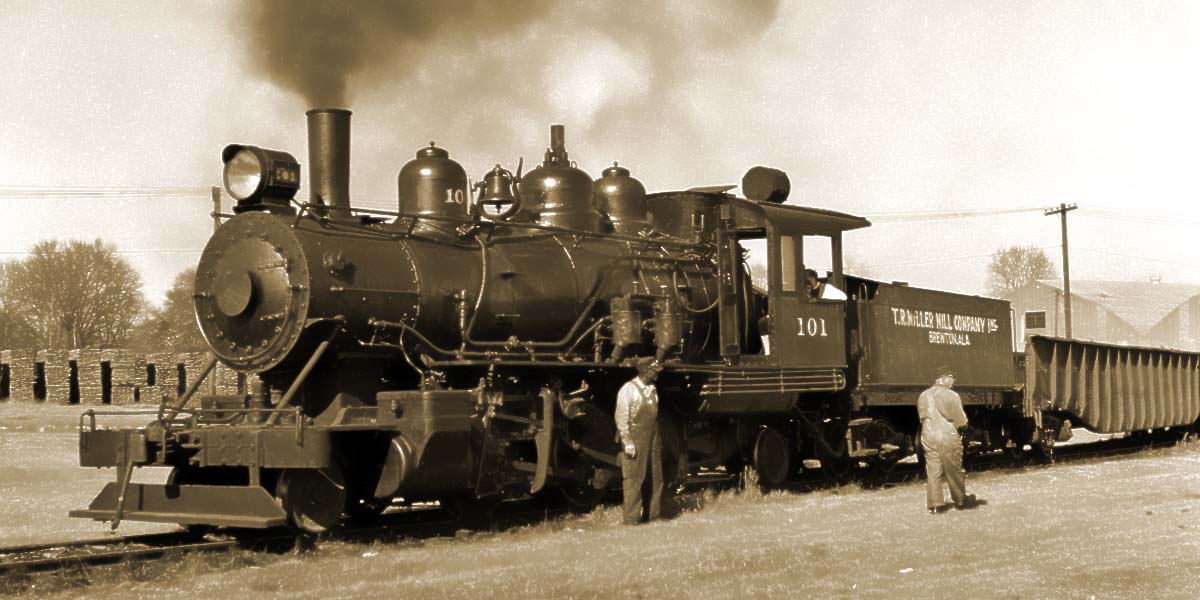

Located in south Alabama, T. R. Miller Mill Company, Inc. is one of the oldest privately held forest product companies in the milling business. Miller relied on steam and rail almost from the very beginning of operations, but by the 1960s, their facility in Brewton had become a steam railfan stopping point: Handsome and nimble Baldwin #101 worked their mill well past the time most of her southern sisters had been scrapped and replaced with diesel-electric power.

ounded in Brewton, Alabama in 1848, the T. R. Miller Mill Company is one of the oldest and most historically significant lumber companies in the southeast. Initially established as a small sawmill by Thomas Richard Miller, the company expanded rapidly due to the demand for lumber in the region. By the late 19th century, it had become a major player in the timber industry, benefitting from the area’s abundant pine forests and strategic access to railroads. Over the years, the company has modernized and adapted to industry changes, maintaining its role as a key economic driver in Brewton and a prominent force in the southern lumber market.

ounded in Brewton, Alabama in 1848, the T. R. Miller Mill Company is one of the oldest and most historically significant lumber companies in the southeast. Initially established as a small sawmill by Thomas Richard Miller, the company expanded rapidly due to the demand for lumber in the region. By the late 19th century, it had become a major player in the timber industry, benefitting from the area’s abundant pine forests and strategic access to railroads. Over the years, the company has modernized and adapted to industry changes, maintaining its role as a key economic driver in Brewton and a prominent force in the southern lumber market.

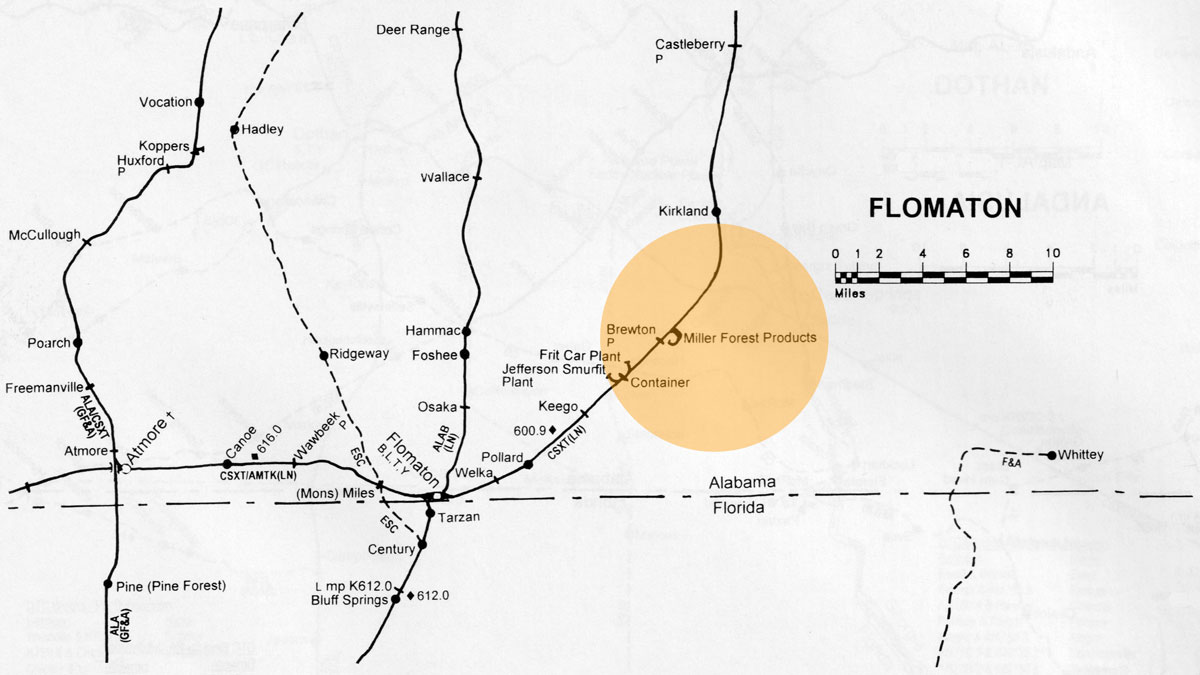

T. R. Miller Mill owns and operates two adjacent wood-handling facilities at its Brewton site, northeast of Mobile and less than 10 miles from the Florida state line. One plant is a standard lumber mill, taking in felled pine trees and producing various sizes and lengths of finished lumber sold to wood treatment finishers and wholesale distributers. Waste wood is sold for pellet production and electrical generation fuel. The second mill, about a mile to the east of the first, is a telephone pole production and treatment plant. Poles are produced to the specification of utility customers. Although all inbound raw materials and some finished products are shipped via trucks, much of the finished lumber is shipped by rail on center-beam flatcars and many of the poles are shipped via side-post log cars.

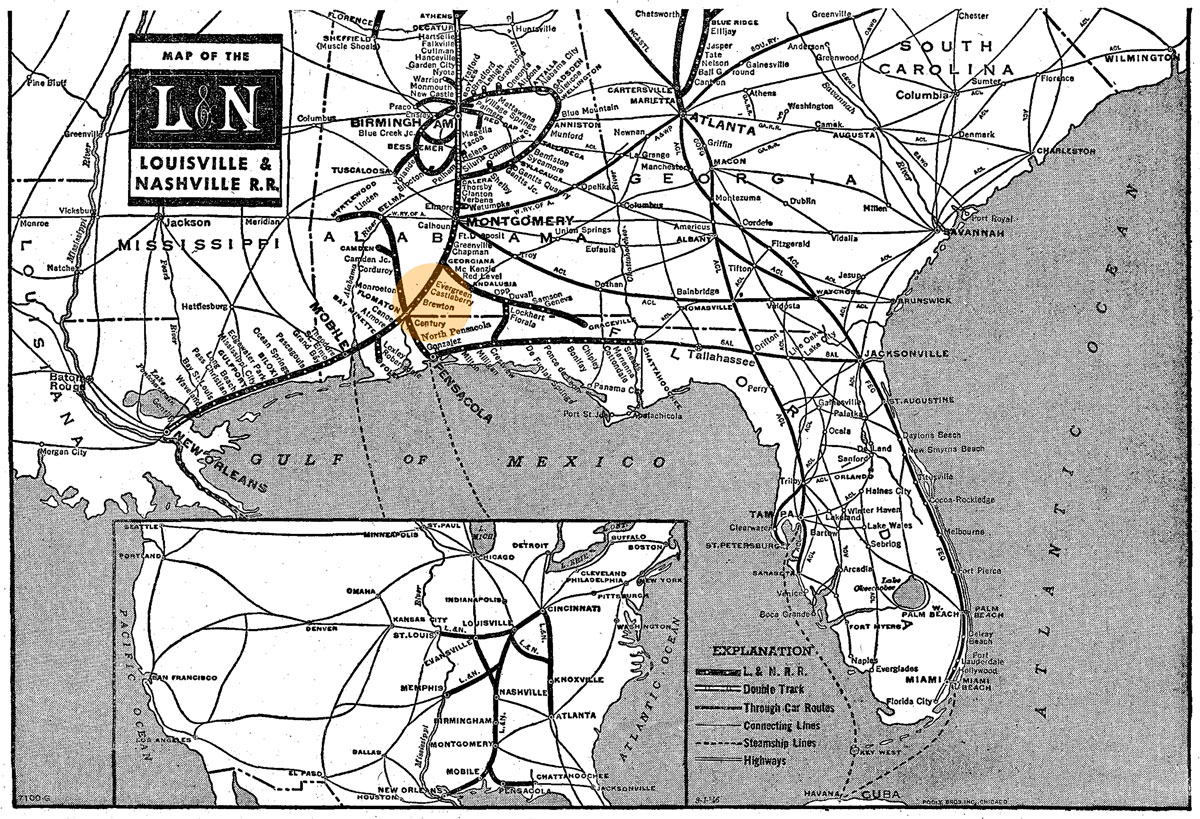

The company maintains a short railroad pike through the woods between loading sidings in the two facilities, and interchange is maintained along Joseph Avenue in Brewton with the CSX Transportation, formerly the Louisville & Nashville mainline between Mobile and Montgomery. The last two steamers to work the property were a handsome "Prairie" and an unusual 2-4-2 "Columbian" tank engine, both of which still survive on display. Today the company makes use of a well-worn General Electric center-cab switcher to shuttle empties for loading and assemble outbound carloads.

The company maintains a short railroad pike through the woods between loading sidings in the two facilities, and interchange is maintained along Joseph Avenue in Brewton with the CSX Transportation, formerly the Louisville & Nashville mainline between Mobile and Montgomery. The last two steamers to work the property were a handsome "Prairie" and an unusual 2-4-2 "Columbian" tank engine, both of which still survive on display. Today the company makes use of a well-worn General Electric center-cab switcher to shuttle empties for loading and assemble outbound carloads.

See also these related scrapbooks:

- Alger-Sullivan Lumber Company in Industrials

- James Houston Jones Historic Park in Preservation

- Mobile River Sawmill Company in Industrials

- Pensacola Museum of Industry in Preservation

Brewton, Al / Nov 2018 / RWH

ocated in Brewton, Alabama, T. R. Miller Mill Company, Inc. is one of the oldest, privately held, forest product companies in business today. Built in 1848, the original mill was one of the first permanent sawmills in the South. Little is known of the original mill except that it was a small water-driven mill, but the choice of location still commands admiration. Not only did Cedar Creek power the mill, it also transported logs from the vast pine forest along its upper reaches and floated the sawn timbers to Pensacola, Florida for export.

ocated in Brewton, Alabama, T. R. Miller Mill Company, Inc. is one of the oldest, privately held, forest product companies in business today. Built in 1848, the original mill was one of the first permanent sawmills in the South. Little is known of the original mill except that it was a small water-driven mill, but the choice of location still commands admiration. Not only did Cedar Creek power the mill, it also transported logs from the vast pine forest along its upper reaches and floated the sawn timbers to Pensacola, Florida for export.

In 1872, ownership changed and the mill operation was incorporated as T. R. Miller Mill Company. This sawmill has operated continuously since 1872, and today is one of the 150 largest sawmills in the U. S. Since 1903, T. R. Miller has manufactured various specialty pine products, and that continues today with an array of pine flooring, siding, and pattern products, as well as a selection of 4 x 8 lattice panels. In 1927, the treated pole and piling division was added, and is now one of the 10 largest producers of poles in the U. S.

1948 Official Guide map / collection

SPV Comprehensive Railroad Atlas / collection

hen [predecessor] Cedar Creek Mill finally got the 'railroad bug' in early 1905, they were the last major sawmill operation in the Brewton area that still relied exclusively on water transportation as the method by which their mill was supplied with logs. But when it came time to get into the railroad logging business, Cedar Creek's initial investment in railroad equipment far exceeded what was in use by their competition in the same vicinity. No narrow-gauge wood rail tram road with little 10 or 20 ton locomotives for Cedar Creek. No sir! They started right off with three large standard-gauge 2-8-0 locomotives running on 56 and 60-pound rail.

hen [predecessor] Cedar Creek Mill finally got the 'railroad bug' in early 1905, they were the last major sawmill operation in the Brewton area that still relied exclusively on water transportation as the method by which their mill was supplied with logs. But when it came time to get into the railroad logging business, Cedar Creek's initial investment in railroad equipment far exceeded what was in use by their competition in the same vicinity. No narrow-gauge wood rail tram road with little 10 or 20 ton locomotives for Cedar Creek. No sir! They started right off with three large standard-gauge 2-8-0 locomotives running on 56 and 60-pound rail.

In October 1991, Thomas R. Miller acquired the controlling interest in Cedar Creek Mill Company. In March 1913, he formally changed the name of the business to T. R. Miller Mill Company, as the company is still known today.

Thomas Lawson, Jr. / Logging Railroads of Alabama / 1997

Brewton, Al / Nov 2018 / RWH

Scrapbooks

Article

Article

Brewton’s T.R. Miller Mill Celebrates a Century-and-a-Half

July 2022

This year, T.R. Miller Mill Co. turns 150 years old.

This year, T.R. Miller Mill Co. turns 150 years old.

Let that sink in.

One hundred and fifty years ago, Ulysses S. Grant was president of the United States, the newly invented internal combustion engine was all the rage, and mill acreage was purchased near Brewton, 46 years before Brewton was Brewton.

Today, with about 208 workers, T.R. Miller Mill Co. is one of the 150 largest softwood lumber producers in America. It is also one of the oldest privately held forest product companies in business today. But to understand this hometown success story, one must understand its history, beginning seven years after the U.S. Civil War.

“When we hire people, they have to hear our story,” says the company’s human resources director, Michael Baty. “We believe this is one of the best companies to work for in the area. Our history illustrates that. It is part of our culture.”

The tale begins as Cedar Creek Mill Co., with a land purchase by Elisha Downing on June 26, 1872. The rest is history — 150 years’ worth.

The tale begins as Cedar Creek Mill Co., with a land purchase by Elisha Downing on June 26, 1872. The rest is history — 150 years’ worth.

A working mill was already in place on Downing’s acquisition, three miles from present day Brewton. But little is known about the pre-1872 days.

Downing developed and operated the fledgling business until 1899. He then sold the company to his son, Wiley Downing, and Thomas Richard (T.R.) Miller and Francis C. Brent. The latter two had been a captive audience, literally.

“Earlier in their lives, Brent and Miller were Confederate prisoners of war held in the same prison,” says Thomas E. McMillan Jr., former director of T.R. Miller Mill Co., and author of “Logging the Mill.” “We are not sure if they knew each other back then.”

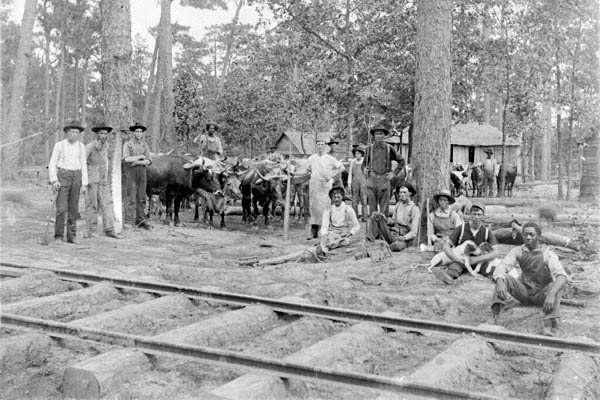

With the team in place, operations continued. “Originally, logs were obtained by oxen pulling carts,” notes McMillan, who is also partner and director of PMT Publishing. The lifeblood of the wood mill, like all mills of the day, was the network of creeks and rivers used for wood transportation. “Logs were off-loaded from ox carts and floated down Cedar Creek,” recalls the company’s former director.

Actually, it was more than off-loading — it was an art. While traveling down the creek, each log was turned “butt-end” first for mill delivery. Log turners were tasked with keeping the logs straight as they flowed downstream.

The men balanced, walked on and jumped from log to log, agile as cats, as the procession moved downstream. According to early company records, good log turners never got their feet wet.

But in the late 1800s and early 1900s the future was upon us, including ox-free deliveries. The ever-trusty beasts of burden, who never questioned company benefits, were phased out in the 1940s.

But in the late 1800s and early 1900s the future was upon us, including ox-free deliveries. The ever-trusty beasts of burden, who never questioned company benefits, were phased out in the 1940s.

In 1892, the company’s main site moved to Brewton, then 7 years old. The flagship location started Brewton operations as a steam-operated mill. After several changes in ownership and various land purchases the company became the T.R. Miller Mill Co.

Rail transportation became the primary means of log transit in 1905 and continued until about 1940, when trucks became Miller’s principal hauler for raw materials and finished lumber.

The Brewton company was not without challengers. Southern yellow pine to Alabama was like the Gold Rush to Alaska — highly sought and perpetually valuable. The lumber business back then, like today, was highly competitive. T.R. Miller persevered where others did not.

“At one time there were at least 27 other sawmills around here,” recalls McMillan. “But others only had the means to cut nearby timber within about a three-mile radius.” Oxen could not travel much past that distance, he adds.

McMillan continues, “In addition, all of those mills were located on or near a creek, which was relied on for log transport. Creeks were not always dependable.”

Occasionally, mills delayed or ceased production due to drought. Operations often shut down as companies waited for a good rain.

“T.R. Miller saw the value of trains and trucks and the necessity to reach out greater distances for timber,” says McMillan. “He also recognized the value of good environmental practices, which also helped the business. While other mills practiced ‘cut and move on,’ Miller replanted his forests.”

“T.R. Miller saw the value of trains and trucks and the necessity to reach out greater distances for timber,” says McMillan. “He also recognized the value of good environmental practices, which also helped the business. While other mills practiced ‘cut and move on,’ Miller replanted his forests.”

In the early days, most of the finished lumber products were transported to Pensacola, Florida, where they were loaded on barges for European customers eagerly waiting across the Atlantic. Today, most of the company’s products are sold domestically.

Since its founding, T.R. Miller Mill Co. has been a family-owned business. Today the primary owners are the Miller, McMillan and W.T. Neal families. Other prominent area families had administrative and/or ownership stakes over the years. Familiar names include Dixon, McGowin, Blacksher, Foshee and Douglas — many of the names you’ll find on Brewton streets signs.

Even if the surnames don’t match, says Baty, the employees seem like family, too. “Approximately 33% of our workforce has been with the company for over 25 years,” he says. “That is unheard of in today’s industry.”

One such employee is Ricky Stanley. Born in nearby Atmore, Stanley moved to Brewton at age 15. He graduated from T.R. Miller High School, named for the mill he would one would day lead as president and CEO.

“I hired into the research and development department of the box plant,” recalls Stanley, a 40-year employee. “I designed wire bound boxes and industrial products.” In 2016 he was named president. He believes T.R. Miller’s opportunities are available to all employees.

“We are a private company where everyone is a person,” says Stanley. “We each have different responsibilities but at the end of the day we are here for a common goal: we make great things from southern yellow pine.”

“We are a private company where everyone is a person,” says Stanley. “We each have different responsibilities but at the end of the day we are here for a common goal: we make great things from southern yellow pine.”

Today’s economy is a puzzle: “The country is in an economic slowdown and inflation is the highest it has been in decades,” he says. But he remains positive. “The housing market is strong and lumber is connected to the housing market. I believe we have underbuilt housing in this country for years. The next several years should be good for us.”

With log trucks rolling into 215 Deer St. and finished product rolling out all day, T.R. Miller Mill Co. has a promising future. The sawmill is budgeted to cut 3.2 million board feet a week, totaling approximately 165 million board feet for the year. In addition, Miller manufactures about 100,000 utility poles annually — one-sixth of the U.S. market.

T.R. Miller’s production schedule is ambitious. It always has been. But not to worry — the company has 150 years of experience.

Emmett Burnett / Business Alabama Magazine

Lagniappe

Another Close Call

Brewton, Al / Nov 2018 / RWH

Snapshots

Snapshots

Pensacola, Fl / 1980s / JCH

Pensacola, Fl / 1980s / JCH

After so many years of working with my father's Miller images, and after so much wonderful correspondence between so many persons about Miller's steam engines and the men who worked them, I was long overdue for a visit to Brewton to see the current operations. Thanksgiving travels to Louisiana gave me the chance to ply southern Alabama and to some photos of the current facility. Although I was 60 years too late to see Mr. Rucker put on a show with kettle #101, I enjoyed putting my father's images of those operations in context. Plus, a southbound CSX coal drag rumbled through Brewton just as I was packing up to head to Mobile. Bonus.

After so many years of working with my father's Miller images, and after so much wonderful correspondence between so many persons about Miller's steam engines and the men who worked them, I was long overdue for a visit to Brewton to see the current operations. Thanksgiving travels to Louisiana gave me the chance to ply southern Alabama and to some photos of the current facility. Although I was 60 years too late to see Mr. Rucker put on a show with kettle #101, I enjoyed putting my father's images of those operations in context. Plus, a southbound CSX coal drag rumbled through Brewton just as I was packing up to head to Mobile. Bonus.

Brewton, Al / May 2019

Brewton, Al / May 2019

Thanks to contacts and introductions made by local Brewton attorney and railfan friend Chuck Johns, Jr., HawkinsRails made an official visit to the T. R. Miller facility so my brother Jack and I could offer framed photographs our father's 1961 pictures of Baldwin #101 and her caretakers Mr. Robert Rucker and Mr. James Jackson. Pictured above, to the right of the company portrait of Mr. Miller himself, are (left) Mr. Daniel Gravely, Operations Manager of the mill and (right) Mr. Thomas E. McMillan, Jr., direct descendent of Miller, member of the Board of Directors, and author of a self-published book on the logging operations and equipment associated with predecessor Cedar Creek Mill Company and successor T. R. Miller Mill. The mill's management was in every way hospitable to our visit, showing us their beautiful office facility, introducing us to various employees (including those in charge of the rail operations), and giving us a driving tour of the entire mill facility. Ours hosts even indulged this diesel roster shot addict as I crawled all over their aging but still-going-strong 65 tonner with replacement EMD controls. The modern Miller Mill is a smart and dedicated lumber operation, full of Southern hospitality and proud of their history as a profitable and responsible timbering firm. It has been an absolute pleasure getting to know more of folks who keep Mr. Miller's original business vision alive.

Thanks to contacts and introductions made by local Brewton attorney and railfan friend Chuck Johns, Jr., HawkinsRails made an official visit to the T. R. Miller facility so my brother Jack and I could offer framed photographs our father's 1961 pictures of Baldwin #101 and her caretakers Mr. Robert Rucker and Mr. James Jackson. Pictured above, to the right of the company portrait of Mr. Miller himself, are (left) Mr. Daniel Gravely, Operations Manager of the mill and (right) Mr. Thomas E. McMillan, Jr., direct descendent of Miller, member of the Board of Directors, and author of a self-published book on the logging operations and equipment associated with predecessor Cedar Creek Mill Company and successor T. R. Miller Mill. The mill's management was in every way hospitable to our visit, showing us their beautiful office facility, introducing us to various employees (including those in charge of the rail operations), and giving us a driving tour of the entire mill facility. Ours hosts even indulged this diesel roster shot addict as I crawled all over their aging but still-going-strong 65 tonner with replacement EMD controls. The modern Miller Mill is a smart and dedicated lumber operation, full of Southern hospitality and proud of their history as a profitable and responsible timbering firm. It has been an absolute pleasure getting to know more of folks who keep Mr. Miller's original business vision alive.

Brewton, Al / May 2019

Brewton, Al / May 2019 / RWH

Links / Sources

- T. R. Miller Mill website

- Brewton’s T.R. Miller Mill Celebrates a Century-and-a-Half — Business Alabama Magazine

- Thomas Lawson, Jr., Logging Railroads of Alabama (Cabbage Stack Publishing, 1997)

- Thomas E. McMillan, Jr., Logging the Mill: Cedar Creek and T. R. Miller Mill Companies (self-published)